Principle of working:

It is well known that vacuum drying is to put raw material to the condition of vacuum for heating and drying, if use vacuum to take air and humidity out, the dry speed will be faster.

Note: if use condensate, the solvent in raw material can be recovered. If use water-ring vacuum pump sets, condensate cannot be used and the investment could be saved.

Features of product:

- Under the condition or vacuum, the boiling point of raw material will decrease and make the pushing force become greater. Therefore for a certain amount of heat radiation, the conduct-ing area of evaporator can be saved.

- The heat source for operation of evaporation may be low pressure steam or surplus heat steam.

- The heat loss of evaporator is less;

- Before drying, the treatment of disinfection may be carried out. During the period of drying, there is no impurity material. It is in conformity with the requirement of GMP;

- It belongs to static drier. So the shape of raw material to be dried cannot be destroyed

Technical parameters:

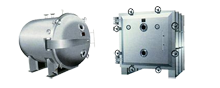

| Name | VD-R600 |

VD-R1000 |

VD-R1400 |

VD-S1500 | |||

| Inside size of chamber (mm) | Ø600×976 |

Ø 1000×1527 |

Ø 1400×2054 |

1500×1400×1220 | |||

| Outer size of chamber (mm) | 1153×810×1020 |

1693×1190×1500 |

2386×1657×1920 |

1513×1924×2060 | |||

| Layers of baking shelf | 4 |

6 |

8 |

8 | |||

| Layers of baking shelf (mm) | 81 |

102 |

102 |

122 | |||

| Size of baking disk (mm) | 310×600×45 |

460×640×45 |

460×640×45 |

460×640×45 | |||

| Number of baking disk | 4 |

12 |

32 |

32 | |||

| Permitted pressure inside the pipe of baking shelf (MPa) | ≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 | |||

| Temperature inside chamber (°С) | ≤150 |

≤150 |

≤150 |

≤150 | |||

| Vacuum inside chamber (MPa) |

-0.9 - 0.096 |

||||||

| Cycle time |

About 3-10 hours For chemical material About 8-20 hours for herb ointment It is up to the material status, liquid content etc. |

||||||

| If not condensate, type and power of vacuum pump(KW) |

SK-1.5-4 kW |

SK-3-5.5 kW |

SW-6-11 kW |

SK-6-11 kW |

|||

| Weight of drying chamber (kg) |

250 |

800 |

1000 |

2100 |

|||

- Comments

Loading comments...