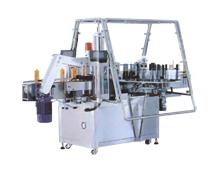

The range of processed products is very wide: plane bottle, square bottle, elliptic bottle, other bottles suitable for marking from two sides. Installation can be applied in food, chemical, cosmetic industries.

Features:

- Using of vertical labeling, and also the special device of a clip, guarantees stability of labeling.

- Using of system of servomotors (Sinano, Japan) allows to label with high speed and precise orientation. It leads to the continuous stable operation for a long time and improves productivi-ty and quality of production.

- A programmable Siemens controller and a touch screen allow to set up and service the ma-chine easily. All alarms are automatically displayed that allows the operator to fix a problem quickly or to carry out necessary changes of process.

- Application of import pneumatic components allows to carry out high-quality labeling with high speed.

- The machine automatically stops when falling bottle, what reduces the waste of labels pre-vents bottles damage.

- In case of the end of a printing tape, the machine stops and alarm signal appears.

- The simple bottles feeding system excludes their damage

- The main parts of the machine are made of SUS304 stainless steel and T6 aluminum alloy that meets GMP requirements.

- Strict requirements to the quality level, the machine passed ISO9001 certification.

Technical parameters:

- Speed of labeling: 100-300 pieces/mines

- Accuracy of labeling: ±0.5mm (depends on verticality of a product);

- Direction: from left - to right or from right – to left;

- Size of a product: diameter 10-120 mm, height 20-300 mm;

- Size of a label: height 15-150 mm, length 25-300 mm;

- Distance between labels: ≥3mm;

- Power supply: 220 V, 50 Hz;

- Compressed air: >5 kgf/cm2;

- Weight: 220kg;

- Overall dimensions: 2280 mm x 1360 mm x 1800 mm.

- Comments

Loading comments...